Lean Leadership. How to Foster Fruit Farmers.

Focussing on “low hanging fruits” is a common management practice to get a team started and also motivated.

But what after that?

Lean Leadership is a way to establish a culture that produces sustainable gains and benefits. Also, it brings the employee into a new role: I like the analogy with the fruit farmer.

(c) Claire Plush

While googling for “fruit farmer” to find a picture for this post, I came across this article WOOMBYE FARMER SOWS SEEDS OF REVIVAL. The Sunshine Coast farmer Stephen Jeffers is portrayed and I quote from the article by Alex Fynes-Clinton/Claire Plush (saltmagazine.com.au):

“Back when I was a kid I thought farming was about driving tractors, planting seeds and picking fruit,” he says. “Little did I know how complicated it actually is. I originally started farming here as a bit of a break before doing something else, but I got drawn right into it.

The challenge is never ending. Every year you’re trying to do it a bit better. The technical side of things really motivates me.”

…

Personally, Stephen is still motivated by the challenges nature throws his way. He’s constantly developing his farming technique and looking to innovate.

What a nice surprise!

All I was looking for was a picture and then I came across a portrait of a man that stumbled into this business when young, found his challenge in producing fruit, is constantly innovating – and successful. Also, I found out that there’s a fruit called “Persimmon”. Great.

The Pain with Lean Projects

Now “lean” doesn’t have a positive co-notation among many of my management colleagues I interact in my work life.

Many remember the boom of “lean” and the projects that resulted in squeezing “waste” out of existing processes. Often consultancies would help mercilessly reach transparency in cost structures and process inefficiencies. Then, the processes were optimized in one big step (including laying off people), the most obvious faults corrected and the low hanging fruits collected.

The colleagues actually doing the work weren’t an activ part in this optimization process. It was experts (internal or external ones) that conceptualized, implemented, collected – and then they were gone. Not a sustainable approach.

It should be different

The simplest introduction to the lean approach I got to know and learned to train (I am a black belt; certified by the Lean Leadership Institute) bases on a very simple core idea.

(c) Lars Diener-Kimmich

Every organization wants to achieve good results.

Mostly everyone will agree that these are the results of good processes. Now, this approach bases on the belief (or some would claim: the fact) that good processes are the result of good employees.

And, then again, these are the result of good managers.

So, eventually we’ll primarily focus on the role of managers. We’ll reflect their every day doing, the picture they have of their employees and their role in the context of establishing continuous improvement.

A note on the side. I don’t believe that “lean” is the answer to all problems. There are situations where the focus on “low hanging fruits” makes more sense. There may also be other more suitable approaches (like “doing nothing”!). In my experience this lean approach is still not well enough understood by many; and it’s tricky, takes time, needs passion, a soft hand and needs to build trust first.

The “Chügelibahn”, establishing a System for Continuous and Team-driven Improvement

I was lucky to have had the projects, sponsors and challenges lign up that I could go in deep and experience it on some really intensive learning projects. I remember a top manager reflecting on this approach. It took him 4 sessions, on-site with the project team to understand it really (and he did!). So, the entry price in the form of time and openness is rather high.

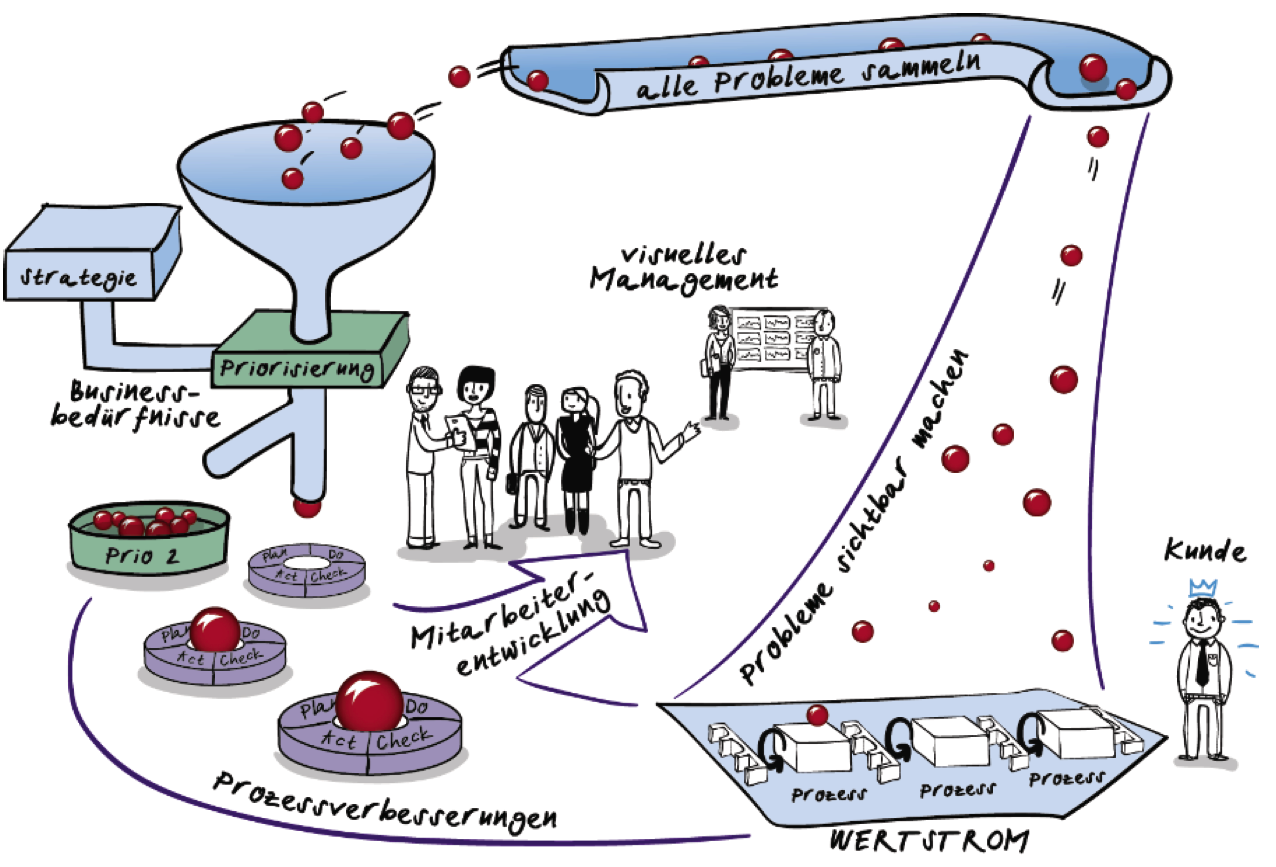

Here’s the “system” that we wanted to establish:

(c) Swisscom

A clear focus on the customer (“Kunde”).

Transparency in the Value Stream (“Wertstrom”) towards the customer.

A culture that allows to talk about and make the problems visible (“Probleme sichtbar machen”).

Collecting and prioritizing (“Priorisierung”) these problems based on Strategy and Business Needs (“Businessbedürfnisse”).

Solving problems one-by-one using PDCA (Plan, Do, Check, Act) to achieve Process Improvements (“Prozessverbesserungen”), continuously. Now, the circle is complete.

And at the core, develop (“Mitarbeiterentwicklung”) your own employees’ problem-solving and innovation competency using Visual Management.

We wrote a short article for HR Today that explains our learning project in a bit more detail (in German).

You and your Employees at the Core

The biggest difference to other ways of improving your process performance comes from the core (see 6., above). Instead of having external experts come in, analyze, re-design and instruct on how to handle the new process, we train managers to establish basic principles to create the necessary environment and then to develop their teams to take on the responsibility of their own value stream.

From my on-the-project experience the building blocks to be successful are:

Learn to look and see, and to be able to talk about what you find out (problems, the way we really work).

Establish a Northern Star that will give you the direction in which you want to improve the performance and output of your value stream. It should be a bit crazy, impossible to reach. You want to be able to continuously (and forever) strive for perfection.

Design a rough sketch “future state” of your value stream. Don’t specify it to every detail. If you do, it’s the best you will get (executed just as specified). Leave room to experiment. It’s amazing what you’ll find out together on the way, that would have been impossible to plan during a specification phase – Something, which you don’t have in this approach.

Formulate the next challenge towards that Northern Star. Make sure it’s so challenging that you don’t know how to get there. So, it will be necessary to experiment. It will move you and your team into the learning zone. That’s how you create room for innovation.

Visualize some clever metrics and track them together with your team. Define how you will be able to recognize that you are making progress. “Clever” means: their fair, can be influenced directly and they allow to track the impact of the measures taken.

Proceed step-by-step. This approach forces you to experiment (that’s good!). Done well, this is the origin for the overall success. Be very disciplined using PDCA (Plan, Do, Check, Act). It’s slow in the beginning. But, as you pick only one problem at a time, you will have results and learnings very quickly. Then act upon them, again, and again, and again …

Establish a weekly “drum beat”, a rhythm, a routine when you meet to discuss the results, learnings and next steps, again, and again, and again …

Give your team and everyone in it (a) responsibility. Adapt your management style towards a solution-oriented way of coaching. Don’t tell your team members what to do. Ask them what they will do. Let them experiment, reflect, learn and adapt. It will constantly raise their innovation and implementation competency.

Protect your team and your value stream from by-passers (often top management :-)) that want to pluck away the low-hanging fruits only, trampling around your orchard (the eco system) you just created.

Now, let’s go be “good managers”. Invest in your employees.

(I can’t track back to the source or author of the above picture. It was forwarded/shared with me on LinkedIn.)

Have a great day and come visit, again.

I’m looking forward to writing more on some of the building blocks mentioned above.